Mitsubishi Lancer Evolution IV (1997) history and technical infos

The Lancer Evolution series, developed expressly to compete in the World Rally Championships and other racing events, seems to have fulfilled its mission of humbling all rivals with an unbroken string of glorious victories. The time-honored system of using data from the track to spawn new ideas and technology to constantly upgrade performance of production models and racing versions has worked extremely well for Mitsubishi engineers, judging from the results.

Just look at the specifications. The Evolution IV boasts 280 PS and 36.0 kg-m torque, which places it squarely in the class of thoroughbred sports cars, making it a hot ride in anyone’s book. Then the Mitsubishi team added capabilities that go beyond what the numbers suggest. Take handling, for instance: Even with enough ponies to let a car this size go and leave you standing, the Evolution IV hugs the tarmac through sheer sophistication of its suspension. And it handles like a dream.

There is an all-new rear suspension and the close-ratio manual transmission to chose from. The body is more rigid, and there is absolutely zero aerodynamic lift at high speeds. Mitsubishi’s exclusive AYC (Active Yaw Control System) also helps push the envelope in the superior-handling department. These points all focus on the car’s top footwork. The 280 PS plant packs plenty of punch, but it’s the whole package that creates that strong sense of unity with the driver.

Mitsubishi’s factory racing team does what all others try to do – it’s all-out war to build better cars than the next guy. But today, it is Mitsubishi’s technology and system and team that are simply leaving the rest of the pack in the dust, and the proof is in the cars and what they do on the racing circuit.

Performance

16-Valve DOHC Intercooler Turbo engine

In the Evolution IV, the highly refined 4G63 power plant has been tweaked beyond belief. New exhaust and cooling systems yield an overall reduction in size and weight, leading to a big boost in power-to-weight ratio. Engine output is now 280 PS / 6500 rpm (JIS) and maximum torque of 36.0 kg-m / 3,000 rpm, largely the work of new twin-scroll turbocharger. A totally tandem structure stretches from the exhaust manifold to the turbine wheel, and it ups torque and response in low and medium range by cutting back pressure. Large-diameter pipes, aft low-restriction mufflers, and single large oval tailpipe add further reduce back pressure. Love that low-end grunt with the 36.0 kg-m torque peak coming at only 3,000 rpm. So it’s powerful enough, with heavy pedal response and compression backdown we crave in everyday driving, making it a megalomania feeder to tool around in.

In the Evolution IV, the highly refined 4G63 power plant has been tweaked beyond belief. New exhaust and cooling systems yield an overall reduction in size and weight, leading to a big boost in power-to-weight ratio. Engine output is now 280 PS / 6500 rpm (JIS) and maximum torque of 36.0 kg-m / 3,000 rpm, largely the work of new twin-scroll turbocharger. A totally tandem structure stretches from the exhaust manifold to the turbine wheel, and it ups torque and response in low and medium range by cutting back pressure. Large-diameter pipes, aft low-restriction mufflers, and single large oval tailpipe add further reduce back pressure. Love that low-end grunt with the 36.0 kg-m torque peak coming at only 3,000 rpm. So it’s powerful enough, with heavy pedal response and compression backdown we crave in everyday driving, making it a megalomania feeder to tool around in.

High-capacity Intercooler

The intercooler’s role is to cool the compressed, superheated air through the turbocharger to boost breathing efficiency. This is crucial in creating a high-output engine. The Evolution IV sports an enlarged, high-capacity intercooler. High efficiency and low pressure loss are optimized with the tube fin shape. This spells an ideal supercharger system. The oversized radiator further helps with the cooling chores. The core is larger, and with an air-cooled type oil cooler, cooling capacity is boosted still further. At the same time, the use of aluminum cuts weight. A new high-capacity water pump also gets into the act.

The intercooler’s role is to cool the compressed, superheated air through the turbocharger to boost breathing efficiency. This is crucial in creating a high-output engine. The Evolution IV sports an enlarged, high-capacity intercooler. High efficiency and low pressure loss are optimized with the tube fin shape. This spells an ideal supercharger system. The oversized radiator further helps with the cooling chores. The core is larger, and with an air-cooled type oil cooler, cooling capacity is boosted still further. At the same time, the use of aluminum cuts weight. A new high-capacity water pump also gets into the act.

The switch in photo 2 is located on the center console. This is to boost cooling capacity with dual-spray injection into the intercooler.

1. High-capacity intercooler

2. Intercooler cooling switch

3. Twin-scroll turbocharger

High Technology for High Power

Cutting-edge engine technology seems to be the key to producing overwhelming motive power. Mitsubishi’s Carman spiral-type air-flow sensor uses an revolutionary detection method that leads to significant reduction in pressure loss, plus a lighter, but more powerful engine. Another big help is a sensor attached to monitor the crankshaft, and accurate control from the large-memory, high-function microcomputer, as well as the semidirect ignition system and use of platinum plugs. The name of the game is higher output, durability and reliability. A metal head gasket holds back pressure better and makes the chance of a blown gasket more remote. The forged pistons increase rigidity, reduce total length, and eliminate the need for steel struts, for a lighter unit overall. Even the connecting rods are stronger than before.

Cutting-edge engine technology seems to be the key to producing overwhelming motive power. Mitsubishi’s Carman spiral-type air-flow sensor uses an revolutionary detection method that leads to significant reduction in pressure loss, plus a lighter, but more powerful engine. Another big help is a sensor attached to monitor the crankshaft, and accurate control from the large-memory, high-function microcomputer, as well as the semidirect ignition system and use of platinum plugs. The name of the game is higher output, durability and reliability. A metal head gasket holds back pressure better and makes the chance of a blown gasket more remote. The forged pistons increase rigidity, reduce total length, and eliminate the need for steel struts, for a lighter unit overall. Even the connecting rods are stronger than before.

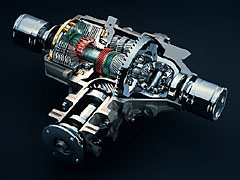

Transmission and Clutch

To do justice to a highly competitive sports car like the Evolution IV, the transmission was designed with mid- to high range foremost in mind, but also to ensure that the gears mesh smoothly at all speed changes. Further, every nook and cranny of the car has been reinforced to handle the higher engine output. First, second, and third gears use double-cone synchromesh. This cuts operating load, making it easier for the driver to shift quickly and accurately. Combined with the strengthening of this synchromesh structure, a lot of scholarship went into improving the linkage, shortening the throw, and creating an all-round sweet shifter. Since the clutch is kept busy in rally racing especially, a small, high-rev, clean-changing type is used. The clutch also has lighter pedal feel. To make the Evolution IV viable for all types of competition, two close-ratio manual transmissions are available.

To do justice to a highly competitive sports car like the Evolution IV, the transmission was designed with mid- to high range foremost in mind, but also to ensure that the gears mesh smoothly at all speed changes. Further, every nook and cranny of the car has been reinforced to handle the higher engine output. First, second, and third gears use double-cone synchromesh. This cuts operating load, making it easier for the driver to shift quickly and accurately. Combined with the strengthening of this synchromesh structure, a lot of scholarship went into improving the linkage, shortening the throw, and creating an all-round sweet shifter. Since the clutch is kept busy in rally racing especially, a small, high-rev, clean-changing type is used. The clutch also has lighter pedal feel. To make the Evolution IV viable for all types of competition, two close-ratio manual transmissions are available.

Gear Ratios (Optional Super-Close-Ratio Five-Speed Manual for the RS)

| Gear | 1st | 2nd | 3rd | 4th | 5th | Reverse | Final ratio of speed reduction |

| Low | 2.785 | 1.950 | 1.444 | 1.096 | 0.825 | 3.416 | 4.875 |

| High | 4.529 |

New Technology

AYC (Active Yaw Control) System

The Evolution IV is very efficient at transferring torque from the heavy-breathing 280-horse power plant to the tarmac, but doesn’t let it overpower the suspension and tires, always affording the driver good control, thanks to Mitsubishi’s AYC technology. The idea was to demonstrate the unparalleled traction you can only get with four-wheel drive, whatever the condition of the road. The basic idea was to regulate yaw though active control of different rotational speeds of the left and right rear wheels. With this control, stepping on the pedal propels you firmly and smoothly in a straight line by sending the right amount of power to each tire, so that the driver doesn’t have to make so many fine steering corrections.

The Evolution IV is very efficient at transferring torque from the heavy-breathing 280-horse power plant to the tarmac, but doesn’t let it overpower the suspension and tires, always affording the driver good control, thanks to Mitsubishi’s AYC technology. The idea was to demonstrate the unparalleled traction you can only get with four-wheel drive, whatever the condition of the road. The basic idea was to regulate yaw though active control of different rotational speeds of the left and right rear wheels. With this control, stepping on the pedal propels you firmly and smoothly in a straight line by sending the right amount of power to each tire, so that the driver doesn’t have to make so many fine steering corrections.

Note: The GRS is standard, RS is optional.

Torque-Transfer Differentials

With a conventional torque-transfer differential, power from the transmission is delivered to an arrangement of ring gears and pinions that allow the left and right tires to receive equal torque as the vehicle travels in a straight line, but to transfer more torque to the outer drive wheel when the vehicle is turning, since that wheel has a greater distance to travel. The problem is that if one wheel slips, such as on ice or mud, torque to the opposite wheel is reduced. This disadvantage is overcome to a large degree by use of a limited-slip differential, in which typically a clutch connects one of the axles and the ring gears. When one wheel encounters low traction, its tendency to spin is resisted by the clutch, thus delivering greater torque to the other wheel. This reduces understeer on a winding road and improves handling overall.

The Effect of Understeering at Low Speeds

While cornering under acceleration, the amount of torque, which is a ratio of lateral g-force to acceleration, determines understeer caused by the rotation of the outer wheel and, if well controlled, allows the driver to trace the intended path.

While cornering under acceleration, the amount of torque, which is a ratio of lateral g-force to acceleration, determines understeer caused by the rotation of the outer wheel and, if well controlled, allows the driver to trace the intended path.

Increased Effectiveness on the Roll and off the Line

On rough roads, where the coefficient of friction of the surface varies, torque is

On rough roads, where the coefficient of friction of the surface varies, torque is

transferred to the side where the tires are not slipping, allowing safe driving or smooth.

The safety afforded by the car’s stability during

The safety afforded by the car’s stability during

acceleration and deceleration, as shown in the illustration above, has won high marks. Pull on the steering wheel is displayed when repeatedly accelerating and decelerating fully with in a 50-meter radius. Equipped with the AYC system, the car needs little corrective steering, and the resulting safety becomes apparent.

Suspension

Front Suspension

The suspension of the Evolution IV has been fined-tuned to achieve perfect handling – good communication between car and driver, and car and road surface. The floating suspension is based on the principle of McPherson Struts. A balance of straight high-speed tracking and satisfying directional changes was achieved by using wider tread, revising the initial alignment, and changing the roll steer and other features. Further, setting the roll center low gives the feel of natural roll while securing traction of the inside wheel during rotation. In addition, a stabilizer is attached to each lower control arm, giving a firm feel to straight-away tracking. Again, enhancing the lateral rigidity of the attachment of the crossmember lower arms, and the use of high-camber firm bearings in the axles enables positive tracking and improved lateral rigidity in cornering. The struts’ curved rigidity has been enhanced, and for race-readiness, the range of damping settings has been expanded. Of course, fine tuning has been thoroughly carried out in such areas as strut damping and spring numbers. Great pains were taken to improve everything from basic functions to capability under extreme conditions.

Newly Developed Multilink Rear Suspension

Knowledge gained trackside has lead to a newly developed double-wishbone-based multilink rear suspension. With revised vehicle structure and geometry, the suspension gives a better feel of holding the road in comparison with the previous multilink trailing-arm based rear suspension. So that it can also endure hard running, all suspension attachment points are connected by ball-joints, and stable alignment changes have been achieved. This greatly improves grip by the unsprung portion and lowers friction during vertical stroke, while ensuring ample rigidity. And in order to stabilize the car’s movements, the toe-in, toe-out and antisquat features have been optimized. Further, turning agility has been enhanced with a big change of camber in the range of the turning stroke. Again, rigidity has naturally been improved and weight reduced overall. The suspension arms are all cast, and the knuckle attachments too have been made more rigid through use of the ball joints, or piroballs. The crossmembers are made of cast aluminum, and the upper control arms of forged aluminum, and at the same time the whole rear suspension has been made lighter. Further, through optimum tuning of damping capacity, spring numbers, and other factors for the shock absorbers in the low-speed range, improvements have been made that are noticeable from throughout the range from Sunday driving to all-out road war.

Front Helical and Rear Mechanical Limited-Slip Differentials

To prevent wheelspin and securely transfer the engine’s power to the road surface, a helical-gear-type limited-slip differential for the four-wheel-drive system is used in front (this is a world’s first for the front wheels of a four-wheel-drive vehicle [optional with the RS]). Compared with the previous viscous limited-slip differential, differential control is greater and more effective, and cornering ability is enhanced. Straight tracking is also excellent. The rear wheels use the usual mechanical limited-slip differential (standard with the RS). Limiting differential control at lower speeds improves head-spin going into a corner. The Evolution has all the right stuff for hedonistic driving.

Body

For Fast Running, a Light and Rigid Body

Somewhere on a driver’s wish list is for a car to give a nice, stable ride during a high-speed chase through bumpy vacant lots – to have a highly rigid body with a suspension and handling that outdo anything on the road today. The Evolution IV represents a further evolutionary change in the Lancer sedan’s body – it is lighter, more rigid and stronger. Reinforcement has been added below the backlight, to the front spring housings and cowl top joints. The amount of spot welding on the door openings is far greater than on a standard car. Further, reinforcing bars have been added where the front and rear suspensions are attached. Further, with the RS, front-strut tower bars and a front-end crossmember have been added. It is not just strong – it has the makings of a fast car that stays together.

Main improvements in structural integrity

(1) Front-strut tower bars (standard on the RS, optional with the GSR)

(1) Front-strut tower bars (standard on the RS, optional with the GSR)

(2) Front-end crossmember (RS)

(3) Front spring-housing and cowl-top combination reinforcement (added)

(4) Reinforcement of the attaching parts of the front suspension (added)

(5) Reinforcement below the backlight (added)

(6) Upper-frame reinforcement (added)

(7) Increased spot welding on the door-opening areas (approx. 200 additional points over a standard car)

(8) Reinforcement to link-bracket toe control (added)

(9) Enlargement of the upper link bracket

(10) Additional reinforcement of the attaching parts of the rear suspension

(11) Reinforcement of the rear spring housings

The above reinforcements add 15% to torsion rigidity

Interior

Momo Leather-Wrapped Steering Wheel

The Evolution IV’s three-spoked steering wheel, wrapped in genuine leather, is made by renowned Italian manufacturer Momo. The wide grip assures secure and quick handling. For the GSR, the driver’s seat airbag system is included.

Dual Airbags (GSR)

In addition to the protection offered by excellent impact-absorbing crush zones and rigid cabin structure, the Evolution IV is equipped with an airbag system for the driver and front-seat passenger. The airbags inflate instantaneously from in front of both seats at the instant of impact. This safety device limits impact to the head area, adding to the protection afforded by the seat belts.

Newest Recaro Seats (GSR)

Recaro seats assure lateral support in hard cornering and give a genuinely spartan image. They also feature infinite-increment reclining and are highly convenient for daily use. Structural changes in the shoulder supports and lateral cushioning, together with a buckskin texture, give added grip. These seats hold you in place no matter how hard you turn the car.

Evolution IV RS (By order from the factory)

The Evolution IV RS – a fighting machine built to compete in pure motor racing. Superfluous weight has been trimmed to the bone, achieving a power-to-weight ratio of 4.50:1. Outclassing pure sports cars, solid performance is the true force of natural selection of the Evolution’s evolution.

Front-strut tower bars/ front-end crossmember/ quick steering-gear ratio are standard.

Photo: The Evolution IV RS racing-specs car (with add-ons and stickers).