Ford Focus WRC history and technical infos

The Ford Focus WRC is the company’s latest weapon in the World Rally Championship. For years Ford’s upper management and marketing was not very keen to invest in rallying. The company’s previous contender, the Escort RS Cosworth and its subsequent Escort WRC, was pushed to the outer limits of evolution and development for almost five years, a very long time by WRC standards. Escorts have been Ford’s rally contenders for more than 25 years and have brought to light many famous drivers such as Stig Blomquist, Ari Vatanen or Juha Kankkunen.

The Escort’s racing results, although not shameful, were not in par with other manufacturer’s entries. Additionally drivers were coming and going to Malcolm Wilson’s team. It was more than time to introduce a new car. Malcolm got the go from Ford management in early 1998 not leaving him too much time to develop the Focus WRC.

The project, codenamed C170, was lead with the outmost secrecy. The Wilson team lead its first tests in General Motors’ testing facilities in Great Britain one of the reasons of this choice being the fact that the GM location was very well protected against spies. The base car (i.e. the street version of the Focus) was engineered with rallying in mind. Ford’s engineers produced a very rigid body shell (present in all street versions of the Focus) and put the accent on torsional rigidity. It is rumored that the Focus body, pictured below, is 10% stiffer than that of the Escort RS Cosworth an already exceptionally stiff one. The effect of this general body stiffness is that the road going versions of the Focus give the driver the impression that they are under-powered especially so since their road holding abilities are very impressive. Additionally the base body being already very stiff, less reinforcement is necessary to that of the race car thus less weight, although, as we’ll see later, weight is one of the drawbacks of the Focus WRC.

Cutaway picture of the Ford Focus WRC car

One last word on the base car. Ford equipped the street versions of the Focus with an advanced multilink rear suspension layout pictured below in its WRC incarnation. This move was intended to homologate a similar suspension layout on the race car. The WRC class car regulations forbid radical changes in suspension layout and attachment points. As a result the everyday Focus driver gets some of the refinement included in the WRC car, much more so than with other WRC cars such as the Toyota Corolla or the Peugeot 206 WRC.

The Ford Focus Multilink rear suspension

The Focus WRC shares no parts with its predecessor or with its street counterpart. Ford took profit of the fact they were designing a brand new car and started from a clean sheet. Apart from the body shell, the engine is new, the Cosworth unit has been replaced by a turbocharged version of the Ford Zetec E 16V engine, and the transmission and drivetrains are completely different compared to those of the previous car. The car was engineered by GĂĽnter Steiner. The name sounds German but GĂĽnter is Italian. His previous work was on the Lancia HF Integrale when it raced for the Italian team Jolly Club. GĂĽnter has also worked for Prodrive on the Subaru Impreza and has, since, joined the Jaguar/Cosworth F1 team in late 2001. GĂĽnter’s replacement for 2002 is Christian Loriaux ex-Prodrive engineer and father of the Impreza P2000 and WRC2001 WRC class cars. Many interesting solutions to common rally car problems are introduced in the Focus WRC and we will examine them one by one in the next pages.

As mentioned earlier the Cosworth power unit has been dropped and replaced by a turbocharged (with no street equivalent) version of the Ford Zetec E 16V engine. Many interesting features are included in the new unit. Unlike its predecessor the Focus WRC uses a transversal engine layout. To improve weight distribution and air intake conditions the engine is inclined by 25° to the rear as compared to the street versions of the Focus. This of course is allowed by WRC class car regulations. The turbocharger used is a TR30 R Garrett AiResearch unit (the Escort WRC used an IHI) which was developed specifically for this application. The TR30 R is a race derivative of the “old” Garrett T3 turbocharger but uses an extremely expensive Mar-M 247 (this nickel-based super alloy is a trademark of Martin Marietta Corporation which became part of Lockheed Martin Inc. in 1995) turbine wheel instead of the INCONEL alloy turbine of its predecessor and has revised geometry to better accommodate the 34mm intake restrictor. All turbo calculations and dimensioning were done with an integrated 34mm restrictor as specified in FIA regulations. The previous Ford contender, the Escort RS Cosworth was using an earlier generation Garrett turbocharger. The Focus WRC car specs are here.

The Focus Zetec turbocharged unit

As you can see from the picture above the exhaust manifold is specific to the Focus WRC application and is quite long, reminding the one used in the RS500 homologation special of the 80s. Long exhaust manifolds allow for a greater quality of gas flow to the turbocharger but have the inconvenience of introducing a relatively important amount of turbo lag. Surely Ford took care of this downside by using the latest generation of turbo anti-lag systems (ALS) on their engine. The exhaust tubing is made out of the precious INCONEL alloy which is very light and heat resistant. Note also that ALS systems seem to be disappearing from the rallying world. Many new teams avoid using them for reliability reasons. These include Toyota and Seat. The engine and more specifically its water pump is what caused major trouble on the first official entry of the Ford Focus. The commissioners of the 1999 Monte Carlo rally refused to accept the car because its water pump was located off the engine in a remote location and was providing independent water flows to each cylinder. This configuration was not part of the FIA homologation sheet Ford had submitted and the team was allowed to race the car after appealing and getting the support of all the other major competitors except Subaru. During the 1999 season the Focus WRC engines were prepared for racing by Mountune. As of the 2000 season the engines are be built and prepared at the Cosworth Racing premises. Many of the Focus WRC engine, transmission and suspension parts are manufactured by the Italian specialist L. M. Gianetti, the choice of an Italian company is certainly related to Steiner himself being Italian.

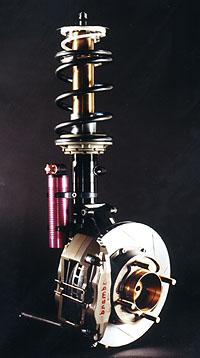

The Focus follows the current trend in World Rallying which is the “smaller the better”. Most of the latest contenders in the WRC introduce very compact cars. This is the case for both Toyota and Peugeot. The Focus is a very compact car with a relatively important wheelbase compared to its length and thus very reduced overhangs. The front and rear tracks are at the limit of what the WRC class allows which is 1550mm. We already spoke about the rear suspension previously so lets have a look at what the front suspension holds. A classic McPherson strut is used with lower wishbones. The layout is pictured below. As you see the strut is very compact and leaves more space to fit other car components around it.

Ford Focus Car Front Suspension

Although this design does not seem revolutionary at first glance it is interesting to note that the dampers have more than the classic adjustable parameters. Usually rally cars use dampers which are adjustable separately for compression and rebound. This is the also the case for the Focus WRC. Ford, however, added new adjustable parameters in their latest dampers. Dampers can now be adjusted depending on the frequency of their piston’s movement in the damper core. To put it more clearly the dampers have different damping characteristics when low frequency movements of the suspension occurs (these are typically related with chassis to damper core vibrations) and different damping characteristics when high frequency movements occur (typically wheel to damper core vibrations). This feature allows for a much more precise handling adjustment. The Reiger dampers used on the Focus WRC use a separate, remote, nitrogen tank which you can see in the picture above (in purple color).

When examining the transmission and drive trains of the Focus WRC it becomes obvious that Ford learned a lot from its competitors. As mentioned earlier the Focus uses a transversally mounted engine. The gear box however is installed longitudinally just like in the Peugeot 206 WRC. This layout necessitates very complex gearing and shafts in order to allow the transmission of torque to all the wheels. There are mainly two reason behind this choice. The first is the necessity to be able to change a gear box in less than 20 minutes, the time during which the World Rally Championship cars are allowed to be serviced. If the box was mounted transversally then the front-left suspension would have to be removed before being able to change the box and the procedure would be much more time consuming. The second reason is that by mounting the gearbox longitudinally the car has a better weight distribution by centering masses inside its wheelbase. In the Ford Focus WRC the weight distribution is 52% on the front wheels and 48% on the rear ones, almost perfect. The gearbox of the Focus WRC is pictured below.

The Ford Focus WRC gearbox

The Ford Focus WRC gearbox

As you can see in the picture above engine torque is picked up at the transfer box, on the right part of the picture, and then distributed to the front wheels through shafts (not shown) in the middle of the box and the rear wheels through the part on the left of the picture. The Focus gear box was developed by XTrac the British gearing specialists and it is of sequential type (i.e. non H-pattern based). Gear changes are operated through a joystick located close to the steering wheel just like in the Toyota Corolla WRC. I am unsure whether the joystick is actuating electronics or mechanical parts. As soon as I find out I’ll let you know.

A frequently neglected part of a rally car is its aerodynamics. Only recently have these cars undergone extensive developments in this field. It’s true that very rarely rally cars reach speeds in excess of 200Km/h. There are however constraints that should not be neglected such as engine compartment air circulation and hot air evacuation, brake system air ducting etc. In this field the Focus excels. The base car has an aerodynamic drag coefficient (a.k.a. Cx) of only 0.32 which was raised in the WRC car (mainly due to greater heat produced by the engine) to 0.36. The Focus is so well designed that there’s almost no need to provide additional down force hence the absence of spoilers.

Like all other major contenders in the WRC, Ford equipped their car with active, hydro-electronically controlled differentials. Already in its first incarnation the Focus was holding three of these devices, one for each axle. The team had to revert to a front and center active differential quite quickly and use a classic mechanical differential at the rear. It is extremely complex to fine-tune a car using three active differentials and, if not perfectly well adjusted, there is no real gain in using active differentials all around especially on slippery surfaces. It is expected that the Ford team will introduce cars using three active differentials at the New Zealand 2000 rally.

Active differentials are usually composed of a classic, free (i.e. non self-locking) device which holds what can be described as a clutch. The clutch progressively operates the differential’s locking and is commanded by electronics and sensors and activated by hydraulic pumps or electric current. The locking characteristics of these differentials vary not only depending on the terrain and its skidding nature but also according to predefined settings that the driver or engineer can set at will, in-car and in real time. For instance the driver can fully lock all differentials at the start line of a special stage in order to favor acceleration and release them immediately afterwards. Hydro-electronic differentials have many advantages over their mechanical counterparts and in particular the ability to act within extremely short time delays (less than 1/10th of a second) as well as to be able to vary their locking abilities continuously, depending on many more parameters than mechanical differentials. Downsides include their price of course, the additional weight of the hydraulic pumps and circuitry and the lack of reliability they introduce when compared to mechanical differentials.

Overall the Ford Focus WRC is well in line with what’s going on in other major company entries in the WRC. After a period of testing and development (the car had only lived for 11 months in January 1999) it will surely be able to at least keep up with its main rivals.

The Focus WRC made an excellent debut at the 1999 Monte Carlo Rally where it finished 3rd overall driven by Colin McRae, ex-Subaru driver and rapidly heading towards superstar level. The second car, driven by the rising French driver Simon Jean-Joseph had less luck but still finished the rally in an honorable 11th overall position. I guess that this is a more than successful start for a brand new car which proved it holds a considerable development potential. Note however that the car was allowed to take part in this event (the 1999 Monte Carlo) under appeal after the FIA scrutinizers had detected a non regular water pump and cooling system (the water pump was mounted in an off-engine location and was ducting water to each cylinder separately). Ford’s appeal was rejected two weeks later thus disqualifying their entry as well as deleting the manufacturer’s and driver points from the WRC. During the 1999 season the Ford team included another member, Thomas Rädstrom a Swedish driver who drove on slippery events (snow and gravel) whereas Jean-Joseph drove on tarmac events. McRae drove on all the season’s events. An interesting anecdote regarding the Focus WRC’s excess weight, compared to its rivals, happened during the final stage of the 1999 Swedish rally. Two drivers were fighting for the third overall position, Didier Auriol in the Corolla WRC and Thomas Rädstrom in the Focus WRC. they were only separated by 10 seconds with Thomas in front. Thomas knew that Didier was able to gap the difference and that he would try everything he could to overtake him. He also had realized the weight disadvantage of the Focus compared to the Corolla.

Ford decided to strip the car of everything unnecessary to finish the rally. When they were done the Focus was still overweight. Thomas then decided that he and his co-driver would not carry their drinking bottles to gain some additional overall weight. The stage was run and Didier managed, through exceptional/heroic driving, to gain a whole 8.1 seconds on Thomas which was, unfortunately for him, not enough to allow him to take the third overall position. That was one of the most memorable moments in recent rally history, especially so because Didier’s driving through that stage was entirely retransmitted on TV, really impressive.

The Ford Focus being a WRC class car it is not available in any street going form. Only cars destined to World Rally Championship events will be built. Additionally, Ford, unlike all other manufacturers, will sale the new car to private teams in its first year of existence. So far no other WRC manufacturer has sold cars they race for less than a year. Note , however, that privately owned Focus WRC are not as evolved as the official ones.

The least one can say is that during the 1999 season Ford Motorsport gave themselves a real chance to win the WRC title. They had some of the best drivers including Colin McRae, the most expensive one, in the World Rally Championship history, a very competitive car and the budget necessary to compete seriously against all other major manufacturers and there are now quite a few around.

In late 1999 Ford announced that Carlos Sainz would join Colin McRae for the 2000 season. Colin’s record of crashes in 1999 brings back memories of old and shows younger fans why he used to be known as McCrash. Shortly after Carlos had signed with Ford the company solicited the FIA for homologation amendments regarding the Focus. These include a new turbocharger, improved aerodynamics (fascia uplift, smaller rear wing spoiler), a repositioning of the clutch relative to the gearbox (the old clutch was causing minor vibrations) and various, minor, engine part changes. In late 2000 Peugeot fugitive and ex-Ford works driver and legend François Delecour joined the Ford team only to strengthen it. François provided more than adequate backing to both Carlos and Colin until he transferred to Mitsubishi RalliArt in 2002 and was replaced by young Markko Märtin.

The car itself underwent numerous modifications and improvements during the 2002 season. These were driven, mainly, by the FIA decision to forbid the use of ceramic materials in the engine bay and the hunt for weight reduction. Other detail modification were aimed at increased reliability and durability and included a modified power steering mounting, modified gear selection lever and integrated onboard electronics.

We hope they’ll get it right this time. We’re counting on you Malcolm, will the European ingenuity prevail Japanese resources? We surely hope so…

Rumor has is that a Focus WRC looking car will be commercialized by Ford in 2001. This car will, allegedly, have front wheel drive, a turbocharged Cosworth engine derivative and around 200Bhp. You can see pictures of the prototype presented in the 1999 Detroit show here. In 2003 a full time 4WD version is likely to follow. Let’s hope these cars do make it to the market one day although I personally feel this is unlikely.